VL 1600 BT50 Vertical Machining center

₹47.00 Lakh

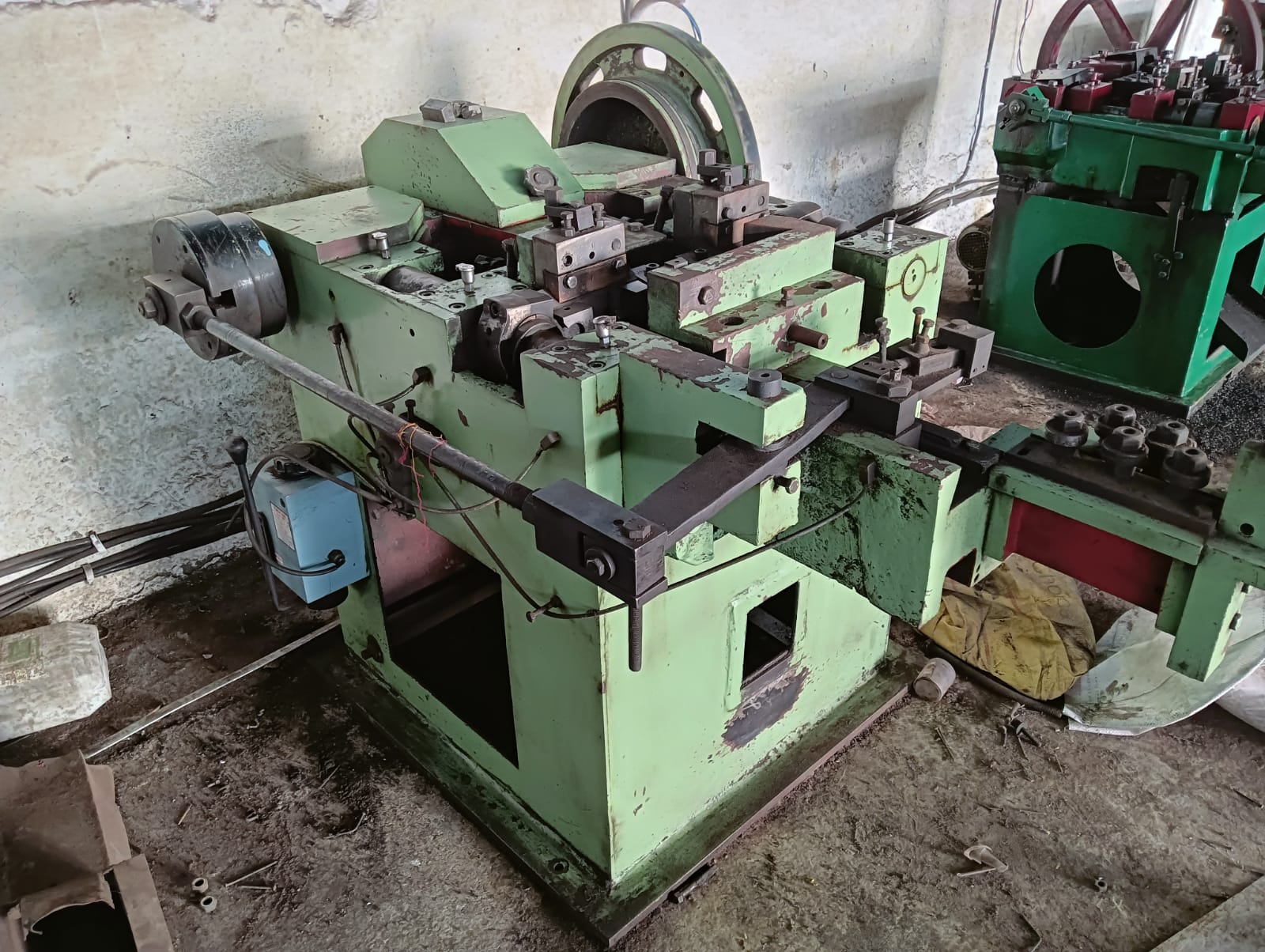

This is a VL 1600 BT50 Vertical Machining center

Product Specification

| Number of Axis | 3 Axis |

| Spindle Speed (RPM) | 5001 – 10000 RPM |

| X-Y-Z Axis Travel | 1,600/700/700mm |

| Model | STM VL 1600 |

| Applicable Industry | Aerospace, Automobile, Die & Mould, Defence, Infrastructure, Medical, Railways |

| Job Material | Aluminium, Cast Iron, Steel |

| Spindle Taper | BT50 |

| Table Working Surface Size | 1,750 * 700mm |

| Table T-Slot Size | 18mm x 5 x 100mm |

| Table Maximum Load | 1,700kg |

Product Description

- ‘A’ shaped structured column with multiple cross ribs offers high cutting performance.

- Ultra Wide base offers very higher stability for big size jobs during heavy duty machining.

- 4 LM Roller Guideways for Y axis ensures uniform performance and dynamics during machining of bigger parts.

- All 3 axes provided with LM Roller Guideways resulting in higher cutting dynamics.

- Imported spindles from Taiwan with G1 balanced grade offers superior finish up to 0.45Ra Value.

- Controller options with latest configuration from Mitsubishi and Fanuc available.

- Options of BT50 available in this model for Higher MRR .

- High efficiency and productivity can be ensured with Fred rate of 10,000mm/min and rapid feed rate of 36 m/min.

- All 3 axes LM Roller Guideways provided with multiple shoes for uniform stability and smooth movement during HSM + HSC.

The VL 1600 BT50 is a specific model of a vertical machining center (VMC) manufactured by a company called “VL”. While I don’t have access to specific information about this machine model, I can provide you with a general overview of what you can expect from a typical vertical machining center.

Vertical machining centers are widely used in various industries for precision machining operations. Here are some general characteristics and features commonly associated with VMCs:

- Structure and Construction: VMCs are built with a solid and rigid structure to ensure stability and minimize vibration during machining. This stability is crucial for achieving high precision and accuracy in the machined parts. The machine’s frame and components are designed to withstand heavy cutting forces and maintain the required rigidity.

- Vertical Spindle: VMCs have a vertically oriented spindle, which is positioned perpendicular to the worktable. The spindle is responsible for rotating the cutting tool at high speeds to perform various machining operations such as milling, drilling, and tapping. The BT50 specification indicates the type and size of the spindle taper, which determines the compatibility of tool holders and tooling systems.

- Axis Movement: VMCs feature a worktable that can move along multiple axes, typically X, Y, and Z. These axes allow for precise positioning and movement of the workpiece relative to the cutting tool. The machine’s control system precisely controls the movement of the axes to execute complex machining operations with high accuracy.

- Automatic Tool Changer (ATC): VMCs are often equipped with an ATC, which automatically changes the cutting tools during the machining process. This enables efficient and uninterrupted machining as different tools can be used for various operations without manual intervention. The capacity of the ATC can vary, ranging from a few tool positions to dozens or even hundreds, depending on the machine’s design.

- Control System and Programming: VMCs are controlled by computer numerical control (CNC) systems. The CNC system interprets the machining program, which is typically generated using CAM software, and controls the machine’s movements, spindle speed, tool changes, and other parameters. Programming includes specifying tool paths, cutting parameters, and instructions for the machine to follow.

- Precision and Accuracy: VMCs are known for their ability to achieve high levels of precision and accuracy. The combination of a rigid structure, precise control systems, advanced tooling, and accurate positioning allows VMCs to produce tight tolerances and excellent surface finishes on machined parts.

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.

This is a VL 1600 BT50 Vertical Machining center

Product Specification

| Number of Axis | 3 Axis |

| Spindle Speed (RPM) | 5001 – 10000 RPM |

| X-Y-Z Axis Travel | 1,600/700/700mm |

| Model | STM VL 1600 |

| Applicable Industry | Aerospace, Automobile, Die & Mould, Defence, Infrastructure, Medical, Railways |

| Job Material | Aluminium, Cast Iron, Steel |

| Spindle Taper | BT50 |

| Table Working Surface Size | 1,750 * 700mm |

| Table T-Slot Size | 18mm x 5 x 100mm |

| Table Maximum Load | 1,700kg |

Product Description

- ‘A’ shaped structured column with multiple cross ribs offers high cutting performance.

- Ultra Wide base offers very higher stability for big size jobs during heavy duty machining.

- 4 LM Roller Guideways for Y axis ensures uniform performance and dynamics during machining of bigger parts.

- All 3 axes provided with LM Roller Guideways resulting in higher cutting dynamics.

- Imported spindles from Taiwan with G1 balanced grade offers superior finish up to 0.45Ra Value.

- Controller options with latest configuration from Mitsubishi and Fanuc available.

- Options of BT50 available in this model for Higher MRR .

- High efficiency and productivity can be ensured with Fred rate of 10,000mm/min and rapid feed rate of 36 m/min.

- All 3 axes LM Roller Guideways provided with multiple shoes for uniform stability and smooth movement during HSM + HSC.

The VL 1600 BT50 is a specific model of a vertical machining center (VMC) manufactured by a company called “VL”. While I don’t have access to specific information about this machine model, I can provide you with a general overview of what you can expect from a typical vertical machining center.

Vertical machining centers are widely used in various industries for precision machining operations. Here are some general characteristics and features commonly associated with VMCs:

- Structure and Construction: VMCs are built with a solid and rigid structure to ensure stability and minimize vibration during machining. This stability is crucial for achieving high precision and accuracy in the machined parts. The machine’s frame and components are designed to withstand heavy cutting forces and maintain the required rigidity.

- Vertical Spindle: VMCs have a vertically oriented spindle, which is positioned perpendicular to the worktable. The spindle is responsible for rotating the cutting tool at high speeds to perform various machining operations such as milling, drilling, and tapping. The BT50 specification indicates the type and size of the spindle taper, which determines the compatibility of tool holders and tooling systems.

- Axis Movement: VMCs feature a worktable that can move along multiple axes, typically X, Y, and Z. These axes allow for precise positioning and movement of the workpiece relative to the cutting tool. The machine’s control system precisely controls the movement of the axes to execute complex machining operations with high accuracy.

- Automatic Tool Changer (ATC): VMCs are often equipped with an ATC, which automatically changes the cutting tools during the machining process. This enables efficient and uninterrupted machining as different tools can be used for various operations without manual intervention. The capacity of the ATC can vary, ranging from a few tool positions to dozens or even hundreds, depending on the machine’s design.

- Control System and Programming: VMCs are controlled by computer numerical control (CNC) systems. The CNC system interprets the machining program, which is typically generated using CAM software, and controls the machine’s movements, spindle speed, tool changes, and other parameters. Programming includes specifying tool paths, cutting parameters, and instructions for the machine to follow.

- Precision and Accuracy: VMCs are known for their ability to achieve high levels of precision and accuracy. The combination of a rigid structure, precise control systems, advanced tooling, and accurate positioning allows VMCs to produce tight tolerances and excellent surface finishes on machined parts.

It is in a good working condition.

No pending loan against the machine

It has been Recently serviced.